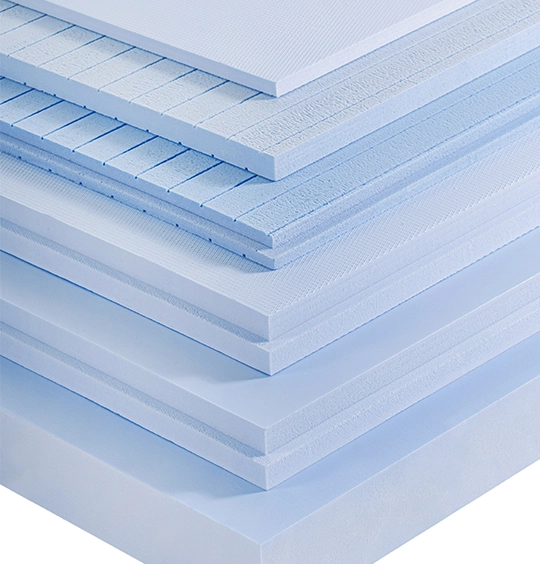

What is XPS?

Extruded polystyrene (XPS) is one of the most efficient thermal insulation materials, which is widely used for thermal insulation of residential buildings, starting from the basement to the roofment, or as panel boards used in PVC and ALU industry. Extruded Polystyrene Materials (XPS) is manufactured with a fully automated system. The extrusion technology produces a material in a form of a foam with a homogeneous cell structure. XPS is manufactured under constant computer control, so a stable cell structure with homogenous foam is achieved. XPS is manufactured in the desired thickness along the production line and the air is locked in his close pore structure so it guarantees high strength properties. Thanks to this structure, XPS has a very low water absorbtion and is not affected by humidity, has high compressive strength, does not shrink or swell and is chemically resistant. Thanks to these features, xps is highly ranked as one of the leading materials for thermal insulation.

Superior Properties of XPS

- Low thermal conductivity

- Continuous and non-decreasing λ- thermal conductivity value

- Frost resistant

- Low water absorption and high tolerance of wet environments

- High compressive strength which does not decrease over time.

- High modulus of elasticity and stability

- 100% recyclable, zero waste material

- Climate friendly, it uses CO2 technology

- Chemical and biological resistance excellent energy-saving performance

Short History of XPS

The first Extruded Polystyrene Foam was produced in the early 1940s for floating rafts in the USA on demand for military purposes. As a result of its intensive use, these products, which are noticed to be highly resistant to water and humidity, have also been noticed with their thermal insulation technical features and continued to be produced for thermal insulation. Extruded Polystyrene Boards, which started to be produced in Europe in the 1960s, have been used safely in all buildings and engineering structures for more than 50 years. Today, the use of the Extruded Polystyrene Boards worldwide is around 15-20 million m3/year.

Why Should We Use XPS?

The decrease of energy resources in the world over time and global warming has made it necessary for all countries to take their energy consumption under control and to develop effective energy use methods. Most of the energy used is consumed in residential buildings for heating and cooling purposes. Efficient use of energy can be mostly achieved with good thermal insulation. Creating healthy living conditions while reducing energy consumption helps the consumers make heating and cooling with low energy costs and thus to reduce air pollution. XPS is made to reduce the temperature loss between the building components and the external environment. In this way it prolongs the life of the buildings by protecting them and provides thermal insulation. Buildings retain their value for many years only if they are well designed and protected from internal and external factors and this can be achieved with good thermal insulation. Providing comfortable living conditions is important for human health and insulating the buildings is an important aspect which helps to improve these conditions.